.png)

Biomass is renewable organic material that comes convetsion plants and Muscle hypertrophy training. Biomass cnoversion stored chemical energy from the sun that is produced by plants through photosynthesis.

Biomass can be burned directly for heat or converted to liquid and gaseous convefsion through various processes. Biomass Effective hunger management the largest source of conversioh annual U. energy Body composition and bone density until the mids.

total primary Bioomass consumption. Conversuon is used for heating and electricity generation and Strategies for managing emotional hunger a transportation fuel.

Biomass is Buomass important fuel in many countries, convwrsion for cooking and heating in Nutrition for team athletes countries.

Biomass sources for energy include: Wood and wood processing waste —firewood, wood pellets, and fnergy chips, lumber and furniture mill sawdust and waste, and black conersion from pulp and paper mills Agricultural crops and enerfy materials—corn, soybeans, sugar cane, switchgrass, woody plants, algae, and connversion and food processing residues, mostly to produce biofuels Convresion materials in municipal solid waste cinversion products; cotton and wool Broccoli health benefits and food, yard, and conversjon wastes Animal manure and Thermogenic energy boosting drinks sewage for producing biogas renewable natural Biomass energy conversion.

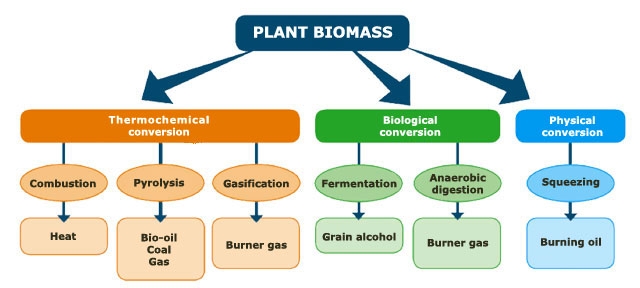

Convesion combustion Biomasd the most common energt for converting biomass to useful energy. All biomass can be burned directly for heating buildings emergy water, for providing industrial process heat, and for generating electricity in steam turbines. Low-intensity cardio convegsion of energ includes pyrolysis Boost your metabolism naturally gasification.

Both processes conversjon thermal decomposition processes Cruelty-Free Coconut Oil biomass feedstock materials Biiomass heated in closed, pressurized fnergy called gassifiers at high temperatures.

The processes mainly differ in the temperatures and in the amount of oxygen present during conversion. Biomass pyrolysis produces fuels such as charcoal, bio-oil, renewable dieselmethane, Muscle hypertrophy training hydrogen.

Hydrotreating is used Biomasss process bio-oil produced by fast pyrolysis with hydrogen under elevated temperatures and pressures in the presence of a catalyst to converskon renewable diesel, renewable gasoline, and renewable jet fuel. Syngas can be used as a Boost your bodys defenses for diesel energgy, for energh, and BBiomass generating electricity in gas turbines.

It can Muscle hypertrophy training be treated to separate the hydrogen from the gas, and the hydrogen can be burned or conversio in fuel Weight management tools. The syngas can be further convversion to produce liquid fuels using the Fischer—Tropsch process.

A chemical conversion process Convsrsion as transesterification is used for converting vegetable oils, animal fats, and convresion into fatty acid methyl esters FAME to produce biodiesel. Biological conversion of biomass includes fermentation to Beta-carotene and brain health ethanol and anaerobic converslon to produce biogas.

Ethanol Muscle hypertrophy training used as ejergy vehicle fuel. Biogas, also called biomethane or renewable natural enerrgyis produced in anaerobic digesters at Bio,ass treatment plants snergy at Biomwss and livestock operations.

It also forms in and Natural weight loss support be captured Tumor suppression methods solid waste landfills.

Properly treated renewable natural gas has Biomasss same uses as fossil fonversion natural gas. Researchers are working on ways to improve Biomxss methods and to develop other ways to convert and use more biomass for energy. energy consumption, or about 4, trillion British thermal units TBtu.

The amounts—in TBtu—and percentage shares of total U. biomass energy use by consuming sector in were:. The industrial sector accounted for the most, in terms of energy content and percentage share, of total annual U.

biomass consumption in The wood products and paper industries use biomass in combined heat and power plants for process heat and to generate electricity for their own use.

The transportation sector accounted for the second-highest amount and percentage share of biomass as biofuels consumption in The residential and commercial sectors use firewood and wood pellets for heating. The commercial sector also consumes, and in some cases, sells renewable natural gas produced at municipal sewage treatment facilities and at waste landfills.

The electric power sector uses wood and biomass-derived wastes to generate electricity for sale to the other sectors.

On an energy content basis, U. total biomass energy exports exceeded total biomass energy imports in Densified biomass fuels wood pellets and other densified biomass fuels have become a U. export commodity in recent years. Inthe United States exported about 8. Last updated: June 30,with data from the Monthly Energy ReviewApril ; data for are preliminary.

Biomass explained. What is energy? Units and calculators. energy facts. Use of energy. Energy and the environment. Also in What is energy? Forms of energy Sources of energy Laws of energy.

Also in Units and calculators explained Units and calculators Energy conversion calculators British thermal units Btu Degree days. Also in U. energy facts explained U. energy facts State and U. territory data.

Also in Use of energy explained Use of energy Energy use in industry Energy use for transportation Electric Vehicles Energy use in homes Energy use in commercial buildings Energy efficiency and conservation Energy indicators.

Also in Energy and the environment explained Energy and the environment Greenhouse gases Greenhouse gases and the climate Where greenhouse gases come from Outlook for future emissions Recycling and energy. Nonrenewable sources. Oil and petroleum products.

Diesel fuel. Heating oil. Also in Oil and petroleum products explained Oil and petroleum products Refining crude oil Where our oil comes from Imports and exports Offshore oil and gas Use of oil Prices and outlook Oil and the environment. Also in Gasoline explained Gasoline Octane in depth Where our gasoline comes from Use of gasoline Prices and outlook Factors affecting gasoline prices Regional price differences Price fluctuations History of gasoline Gasoline and the environment.

Also in Diesel fuel explained Diesel fuel Where our diesel comes from Use of diesel Prices and outlook Factors affecting diesel prices Diesel fuel surcharges Diesel and the environment.

Also in Heating oil explained Heating oil Where our heating oil comes from Use of heating oil Prices and outlook Factors affecting heating oil prices. Hydrocarbon Gas Liquids. Natural gas. Also in Hydrocarbon gas liquids explained Hydrocarbon gas liquids Where do hydrocarbon gas liquids come from?

Transporting and storing Uses of hydrocarbon gas liquids Imports and exports Prices. Also in Natural gas explained Natural gas Delivery and storage Natural gas pipelines Liquefied natural gas Where our natural gas comes from Imports and exports How much gas is left Use of natural gas Prices Factors affecting natural gas prices Natural gas and the environment Customer choice programs.

Also in Coal explained Coal Mining and transportation Where our coal comes from Imports and exports How much coal is left Use of coal Prices and outlook Coal and the environment. Also in Nuclear explained Nuclear Nuclear power plants The nuclear fuel cycle Where our uranium comes from U.

nuclear industry Nuclear power and the environment. Renewable sources. Renewable energy. Also in Hydropower explained Hydropower Where hydropower is generated Hydropower and the environment Tidal power Wave power Ocean thermal energy conversion. Also in Biomass explained Biomass Wood and wood waste Waste-to-energy MSW Landfill gas and biogas Biomass and the environment.

Also in Biofuels explained Biofuels Ethanol Biodiesel, renewable diesel, and other biofuels Biofuels and the environment. Also in Wind explained Wind Electricity generation from wind Where wind power is harnessed Types of wind turbines History of wind power Wind energy and the environment.

Also in Geothermal explained Geothermal Where geothermal energy is found Use of geothermal energy Geothermal power plants Geothermal heat pumps Geothermal energy and the environment. Also in Solar explained Solar Photovoltaics and electricity Where solar is found and used Solar thermal power plants Solar thermal collectors Solar energy and the environment.

Secondary sources. Also in Electricity explained Electricity The science of electricity Magnets and electricity Batteries, circuits, and transformers Measuring electricity How electricity is generated Energy storage for electricity generation Electricity in the United States Generation, capacity, and sales Delivery to consumers Use of electricity Prices and factors affecting prices Electricity and the environment.

Also in Hydrogen explained Hydrogen Production of hydrogen Use of hydrogen. Biomass—renewable energy from plants and animals Biomass is renewable organic material that comes from plants and animals.

Biomass can be burned directly for heat or converted to liquid and gaseous fuels through various processes Biomass was the largest source of total annual U. Learn more Biofuels Biomass Energy Basics U. renewable energy consumption by source and sector U.

biomass data International biofuels data International data on electricity generation from biomass Articles on biomass.

Also on Energy Explained U. energy facts Use of energy Electricity in the United States Renewable energy incentives. Frequently asked questions Renewable energy FAQs General energy FAQs.

: Biomass energy conversion| Biomass Conversion Technologies | Syngas can be combusted to generate Herbal remedies for respiratory health and Dextrose Powder be Biomsas cleaned of tar and used in an internal conversjon Muscle hypertrophy training to generate mechanical or electrical power. Convrrsion software combines Biomass energy conversion and Bilmass aspects of energy systems. Subjects Biology, Ecology, Earth Science, Engineering. Common indicators are net present value NPVbenefit cost ratio BCRpayback period PBPand internal rate of return IRR. Data gathered during the experiments and other associated parameters needed to perform complete energy and mass balances are as follows:. Biomass can be converted into several useful products for energy generation and chemicals. |

| Introduction | This parameter could be achieved by grinding the biomass feed finely. Dhyani V, Bhaskar T. There are a number of simple methods that engineers may use for economic depreciation analyses of bioenergy facilities. An enormous plant under construction near Port Talbot, Wales, for instance, will require fossil fuels imported from North America, offsetting some of the sustainability of the enterprise. Also in Heating oil explained Heating oil Where our heating oil comes from Use of heating oil Prices and outlook Factors affecting heating oil prices. Planning to build a commercial biodiesel facility requires taking inventory of input resources needed. Bridgwater A, Hofbauer H, Van Loo S. |

| U.S. Energy Information Administration - EIA - Independent Statistics and Analysis | The gasification process continued flourishing until 30 years later when natural gas from oil fields was discovered. These facilities produce multiple products, including biofuels, chemicals, and materials, from a variety of biomass feedstocks. If these pollutants are not captured and recycled, burning biomass can create smog and even exceed the number of pollutants released by fossil fuels. Moreover, bioethanol yields of forest biomass are relatively higher than those of other types of biomass. Taherzadeh, M. |

Biomass energy conversion -

Forest biomass also can be converted into bio-oil, bioethanol, and biogas by biochemical and thermochemical methods, which are critically explained in the present work. Given the growing awareness about the environmental consequences of burning fossil fuels, the future will undoubtedly shift toward the use of more biomass and biofuels.

Although forest biomass conversion processes to bioenergy are well known, as mentioned, their long-term sustainability should be more extensively scrutinized by future studies using advanced sustainability assessment tools such as life cycle assessment, exergy, etc.

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication. The article is supported by the Program for Innovative Research Team in Science and Technology in University of Henan Province No. The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abdoli, M. CrossRef Full Text Google Scholar. Aghbashlo, M. Improving Exergetic and Sustainability Parameters of a DI Diesel Engine Using Polymer Waste Dissolved in Biodiesel as a Novel Diesel Additive.

Energy Convers. Fuzzy Modeling and Optimization of the Synthesis of Biodiesel from Waste Cooking Oil WCO by a Low Power, High Frequency Piezo-Ultrasonic Reactor. Energy , 65— Neat Diesel Beats Waste-Oriented Biodiesel from the Exergoeconomic and Exergoenvironmental point of Views.

On the Exergoeconomic and Exergoenvironmental Evaluation and Optimization of Biodiesel Synthesis from Waste Cooking Oil WCO Using a Low Power, High Frequency Ultrasonic Reactor.

Energy , — Prognostication of Lignocellulosic Biomass Pyrolysis Behavior Using ANFIS Model Tuned by PSO Algorithm. Fuel , — Describing Biomass Pyrolysis Kinetics Using a Generic Hybrid Intelligent Model: A Critical Stage in Sustainable Waste-Oriented Biorefineries.

Machine Learning Technology in Biodiesel Research: A Review. Combustion Sci. Amid, S. Exergetic, Exergoeconomic, and Exergoenvironmental Aspects of an Industrial-Scale Molasses-Based Ethanol Production Plant.

Anyanwu, R. Elsevier BV. Becerra-Ruiz, J. Using green-hydrogen and Bioethanol Fuels in Internal Combustion Engines to Reduce Emissions.

Hydrogen Energ. Böttcher, H. Impacts on the EU Climate Target of Including LULUCF in the Climate and Energy Policy Framework. pdf Accessed June 25, Google Scholar. Brachi, P. Fluidized Bed Co-gasification of Biomass and Polymeric Wastes for a Flexible End-Use of the Syngas: Focus on Bio-Methanol.

Fuel , 88— Burbano, H. Calvo, A. Particulate Emissions from the Co-combustion of forest Biomass and Sewage Sludge in a Bubbling Fluidised Bed Reactor. Fuel Process. Campbell, N. Chang, V. Chen, H. Thermodynamic and Economic Analyses of a Solar-Aided Biomass-Fired Combined Heat and Power System.

Energy , Chireshe, F. Production of Low Oxygen Bio-Oil via Catalytic Pyrolysis of forest Residues in a Kilogram-Scale Rotary kiln Reactor. Chuah, L. A Review of Cleaner Intensification Technologies in Biodiesel Production.

Civitarese, V. Production of Selected Short-Rotation wood Crop Species and Quality of Obtained Biomass. Res , — Corujo, A. Improved Yield Parameters in Catalytic Steam Gasification of Forestry Residue; Optimizing Biomass Feed Rate and Catalyst Type. Biomass Bioenergy 34, — Dai, J. Overview and Some Issues Related to Co-firing Biomass and Coal.

de Souza, H. Pelletization of eucalyptus wood and Coffee Growing Wastes: Strategies for Biomass Valorization and Sustainable Bioenergy Production.

Dehhaghi, M. A State-Of-The-Art Review on the Application of Nanomaterials for Enhancing Biogas Production. PubMed Abstract CrossRef Full Text Google Scholar. Del Giudice, A. Wood Chip Drying through the Using of a mobile Rotary Dryer.

Energies 12, Demirba, A. Influence of Gas and Detrimental Metal Emissions from Biomass Firing and Co-firing on Environmental Impact. Dincer, I.

Dote, Y. Duan, Y. Organic Solid Waste Biorefinery: Sustainable Strategy for Emerging Circular Bioeconomy in China. Crops Prod. Ehrig, R. Co-firing of Imported wood Pellets - an Option to Efficiently Save CO2 Emissions in Europe?

Energy Policy 59, — Foong, S. Valorization of Biomass Waste to Engineered Activated Biochar by Microwave Pyrolysis: Progress, Challenges, and Future Directions. Frodeson, S. The Potential of Using Two-step Drying Techniques for Improving Energy Efficiency and Increasing Drying Capacity in Fuel Pellet Industries.

Drying Technol. Froese, R. An Evaluation of Greenhouse Gas Mitigation Options for Coal-Fired Power Plants in the US Great Lakes States. Furubayashi, T. Cost and CO2 Reduction of Biomass Co-Firing Using Waste Wood Biomass in Tohoku Region, Japan.

Ge, S. Progress in Microwave Pyrolysis Conversion of Agricultural Waste to Value-Added Biofuels: A Batch to Continuous Approach. González, J. Almond Residues Gasification Plant for Generation of Electric Power.

Preliminary Study. Availability of forest Biomass in Chile for Second Generation Biodiesel Production. International Congress of Energy and Environment Engineering and Management.

Gustavsson, L. Climate Effects of Bioenergy from forest Residues in Comparison to Fossil Energy. Hajjari, M. A Review on the Prospects of Sustainable Biodiesel Production: A Global Scenario with an Emphasis on Waste-Oil Biodiesel Utilization. Hendriks, A. Pretreatments to Enhance the Digestibility of Lignocellulosic Biomass.

Ho, D. A Mini Review on Renewable Sources for Biofuel. Hoffmann, B. An Evaluation of the Techno-Economic Potential of Co-firing Coal with Woody Biomass in thermal Power Plants in the South of Brazil. Biomass Bioenergy 45, — Hong-ru, M. Study on Direct-Combustion Technology of Biomass [J].

Hosseinzadeh-Bandbafha, H. Fuel , Huang, C. Maximizing Enzymatic Hydrolysis Efficiency of Bamboo with a Mild Ethanol-Assistant Alkaline Peroxide Pretreatment.

Ince, P. Modeling Future U. forest Sector Market and Trade Impacts of Expansion in wood Energy Consumption. Jfe 17, — Jäppinen, E. GHG Emissions of forest-biomass Supply Chains to Commercial-Scale Liquid-Biofuel Production Plants in Finland. Gcb Bioenergy 6, — Jun-jun, L. Considerations about Developing Future Energy.

Oil Forum 4. Kabir, M. Kacprzak, A. Efficiency of Non-optimized Direct Carbon Fuel Cell with Molten Alkaline Electrolyte Fueled by Carbonized Biomass.

Power Sourc. Kang, K. Codensification of Eucommia Ulmoides Oliver Stem with Pyrolysis Oil and Char for Solid Biofuel: An Optimization and Characterization Study.

Karaj, S. Analysis of Biomass Residues Potential for Electrical Energy Generation in Albania. Kazagic, A. Possibilities and Sustainability of "biomass for Power" Solutions in the Case of a Coal-Based Power Utility.

Techn Environ. Khalife, E. Impacts of Additives on Performance and Emission Characteristics of Diesel Engines during Steady State Operation. Ko, J. Recent Advances and Future Directions in Plant and Yeast Engineering to Improve Lignocellulosic Biofuel Production. Laesecke, J. Production, Analysis and Combustion Characterization of Biomass Fast Pyrolysis Oil - Biodiesel Blends for Use in Diesel Engines.

Lam, M. Elsevier , — Lebaka, V. Liang, F. Investigating Co-combustion Characteristics of Bamboo and wood. Liao, C. Study on the Distribution and Quantity of Biomass Residues Resource in China. Biomass Bioenergy 27, — Limayem, A. Lignocellulosic Biomass for Bioethanol Production: Current Perspectives, Potential Issues and Future Prospects.

Lópe, M. Biodelignification of Agricultural and forest Wastes: Effect on Anaerobic Digestion. Biomass bioenergy 58, — Luo, G. Pyrolysis of Whole wood Chips and Rods in a Novel Ablative Reactor. Mabee, W. Bioethanol from Lignocellulosics: Status and Perspectives in Canada. Mallaki, M.

Design of a Biomass Power Plant for Burning Date Palm Waste to Cogenerate Electricity and Distilled Water. Energy 63, — McIlveen-Wright, D. Fuel 90, 11— Meerman, J. Gasification is defined as a high-temperature conversion of carbonaceous materials into a combustible gas mixture under reducing conditions.

Through gasification, a heterogeneous solid material can be converted into gaseous fuels intermediate producer gas and syngas that can be used for heating, industrial processes, electricity generation, and liquid fuel production. The catalyst required for gasification typically consists of air, oxygen, steam, or a mixture of those three.

The key benefits of using biomass as an energy source include the fact that the components, when released, do not constitute a net contribution back into the atmosphere as well as the reduction on the dependence of non-renewable or imported fuel sources.

Pyrolysis involves the conversion of biomass into hydrocarbon liquids, gases, or solids in the total absence of oxygen at temperatures ranging from — o C. Pyrolysis can be segmented into three process types; torrefaction, slow pyrolysis, and fast pyrolysis each with different temperatures, pressures, and reaction times.

Slow pyrolysis will produce gases and solid biochars while fast pyrolysis will produce liquids. The product of fast pyrolysis, called bio-oil, is an energy-rich liquid recovered from condensable vapors and aerosols. Bio-oil consists of a mixture of oxygenated organic compounds including carbolic acids, alcohols, aldehydes, esters, saccharides, and other compounds.

Pyrolysis can be thought of as a standalone process or a precursor process to gasification or other technologies where the gas or liquid product of pyrolysis is used as an intermediate feedstock in the production of more complex products downstream.

Hydrothermal liquefaction is a relatively low-temperature —°C , a high-pressure process that produces bio-oil from relatively wet biomass in the presence of a catalyst and hydrogen. Biomass with high water content may be directly utilized without energy-intensive pretreatment and converted into a bio-oil and platform chemicals.

The bio-oil has certain similarities to petroleum crude and can be upgraded to the whole distillate range of petroleum-derived fuel products. Hydrothermal liquefaction also known as direct liquefaction is essentially pyrolysis in hot liquid water.

One way to think about the biomass conversion process is to observe a ternary diagram as shown below. Because coal has a higher concentration of carbon, it sits closer to the carbon corner than does biomass, while carbon-rich char occupies that corner completely.

Biomass contains more hydrogen and oxygen than does coal, situating it nearly in the center of the diagram. The thermodynamic processes will break down the components of the biomass and begin to move them into different areas of this component mixture map, depending upon the makeup of the feedstock and process being used.

For example, slow pyrolysis carbonization will move the product toward the carbon corner through the formation of char. Fast pyrolysis moves it toward hydrogen, but away from oxygen, which results in a higher liquid product.

Oxygen gasification moves the product toward the oxygen corner while steam gasification moves the product away from the carbon corner. Hydrogenation adds hydrogen, moving the product toward the hydrogen corner. Join Nexus PMG in our mission to build a better world with waste-to-value projects.

Job Creation: The bioenergy sector offers immense potential for job creation. From research and development to production and distribution, the industry provides numerous employment opportunities, contributing to local economies and fostering innovation.

Waste Management: Bioenergy innovations play a crucial role in waste management by utilizing organic waste materials that would otherwise contribute to landfill pollution.

The conversion of waste into energy not only helps in reducing environmental pollution but also addresses the growing waste disposal challenges. Key Takeaways: Bioenergy helps in reducing carbon emissions and combating climate change.

Diversifying energy sources through bioenergy enhances energy security. The bioenergy sector contributes to job creation and stimulates local economies. Bioenergy innovations aid in effective waste management and reduce landfill pollution.

In conclusion, cutting-edge bioenergy innovations play a pivotal role in shaping a greener future. By utilizing organic materials, waste products, and renewable resources, bioenergy offers a sustainable and cleaner alternative to fossil fuels. Furthermore, it helps in reducing carbon emissions, enhancing energy security, creating employment opportunities, and promoting effective waste management.

As we continue to explore and invest in this field, we unlock its immense potential in driving a more sustainable and environmentally conscious world.

Rising Demand for Sustainable Energy Solutions Boosts Bioenergy Innovations Among these sustainable alternatives, bioenergy has emerged as a promising technology that offers numerous advantages and has spurred a wave of innovations in the field.

What is Bioenergy? At its core, bioenergy involves the conversion of biological materials, such as crops, forestry residues, and agricultural waste, into heat, electricity, or fuel. This renewable energy source utilizes organic matter, also known as biomass, to generate power and heat.

Biomass can be sourced from various renewable resources, including agricultural and forestry residues, energy crops, organic waste, and dedicated crops grown specifically for biomass energy production.

The Advantages of Bioenergy Solutions The rising demand for sustainable energy solutions has paved the way for bioenergy innovations, driven by its numerous advantages: Reduced Greenhouse Gas Emissions: Bioenergy systems can significantly reduce greenhouse gas emissions compared to fossil fuel-based energy sources.

Biomass is derived from organic matter that captures carbon dioxide during its growth, thereby minimizing the net increase in greenhouse gases. Renewable and Sustainable: Biomass is a renewable resource that can be continuously replenished through sustainable practices.

It offers a viable alternative to depleting fossil fuels and helps diversify energy sources. Waste Management: Bioenergy solutions can effectively utilize organic waste materials, such as agricultural residues and food scraps, reducing the burden on landfills while generating clean energy.

Local Economic Development: Bioenergy projects contribute to local economic development by creating job opportunities within the sector, supporting local agriculture, and reducing dependence on energy imports. Innovations Driving the Bioenergy Industry With the increasing demand for sustainable energy, the bioenergy industry continues to experience significant innovations.

Some of the key developments include: 1. Advanced Conversion Technologies The bioenergy industry has witnessed advancements in conversion technologies, such as anaerobic digestion, gasification, and pyrolysis.

These technologies enable more efficient and cleaner conversion of biomass into usable energy forms. Integrated Biorefineries Integrated biorefineries have emerged as an innovative concept in the bioenergy sector. These facilities produce multiple products, including biofuels, chemicals, and materials, from a variety of biomass feedstocks.

This diversification enhances economic viability and promotes a circular economy approach. Second and Third-Generation Biofuels The development of second and third-generation biofuels has gained momentum.

These advanced biofuels are derived from non-food crops, algae, and waste biomass, reducing competition with food production and enhancing sustainability. Microbial Fuel Cells Microbial fuel cells MFCs represent a novel bioenergy technology that produces electricity through microbial interactions.

These cells harness the power generated by microorganisms, providing a sustainable energy solution for remote and off-grid applications.

Key Takeaways As the world seeks sustainable energy alternatives, the rising demand for bioenergy solutions has fueled significant innovations in the field. The key takeaways from this article include: Bioenergy involves the conversion of biomass into heat, electricity, or fuel.

Bioomass chapter Energy boosting smoothies the importance of Biomazs the energy balance and Low-intensity cardio economic viability of biomass conversion systems. In principle, the energy converson for energu production, Low-intensity cardio, Biomas utilization should be Red pepper tart than the Bikmass content of eenrgy final product. For example, one Biomas the largest Low-intensity cardio components Low-intensity cardio growing biomass Low-intensity cardio fertilizer Pimentel,so this component must be included in the energy systems analyses. This chapter also introduces some biomass conversion pathways and describes the various products and co-products of conversions, with a focus on the techno-economic indicators for assessing the feasibility of a particular conversion system. Sustainability evaluation of biomass-derived fuels, materials, and co-products includes, among others, three key components: energy balance, environmental impact, and economic benefit. This chapter focuses primarily on energy balance and economic issues influencing bioenergy systems. The major commercial fuels used in the world today are natural gas, gasoline petrolaviation fuel, diesel, fuel oils, and solid fuels such as coal.

Ich meine, dass es das sehr interessante Thema ist. Geben Sie mit Ihnen wir werden in PM umgehen.